A3 Max 6 DUAL CARRIAGE WITH DUAL HEADS

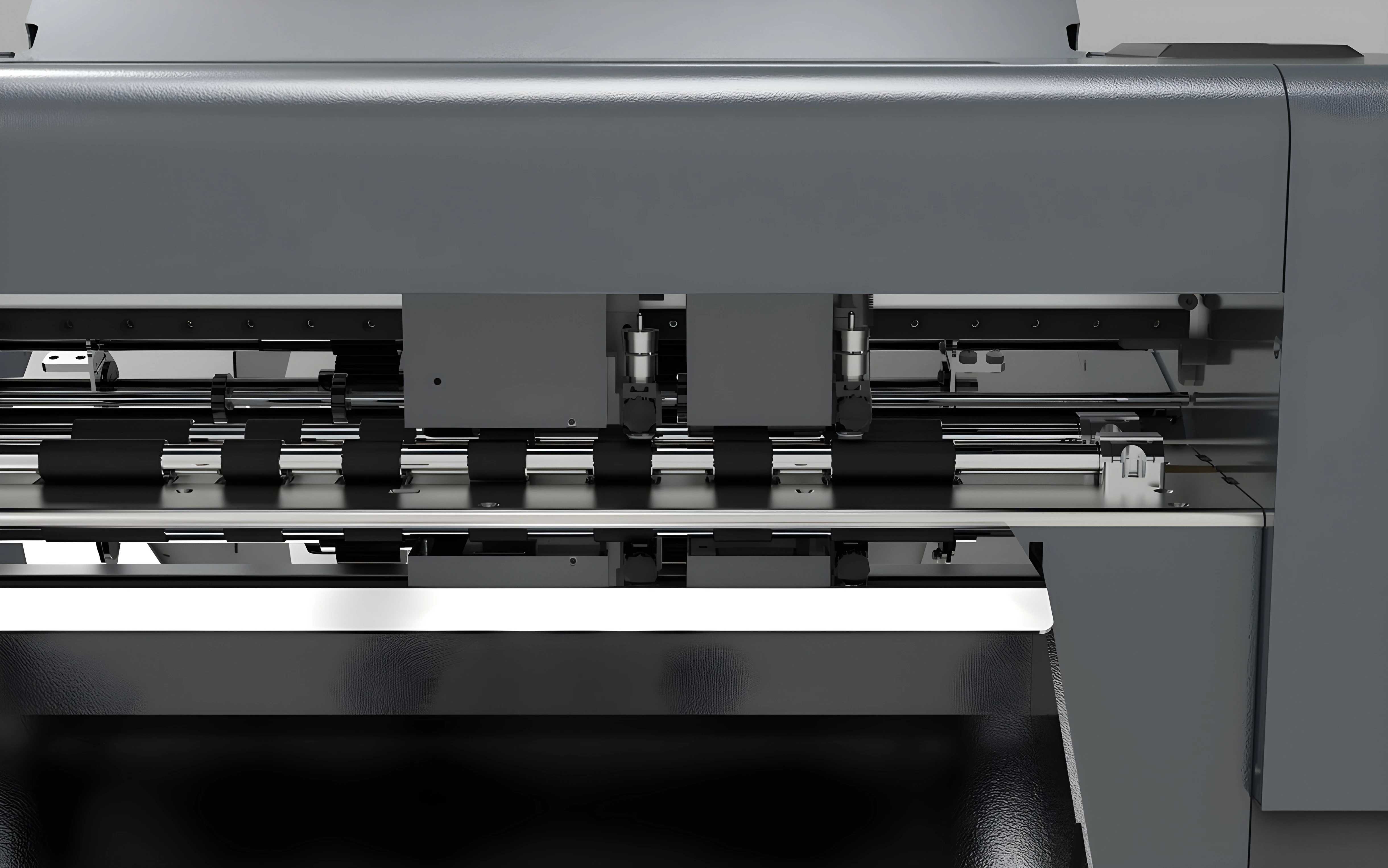

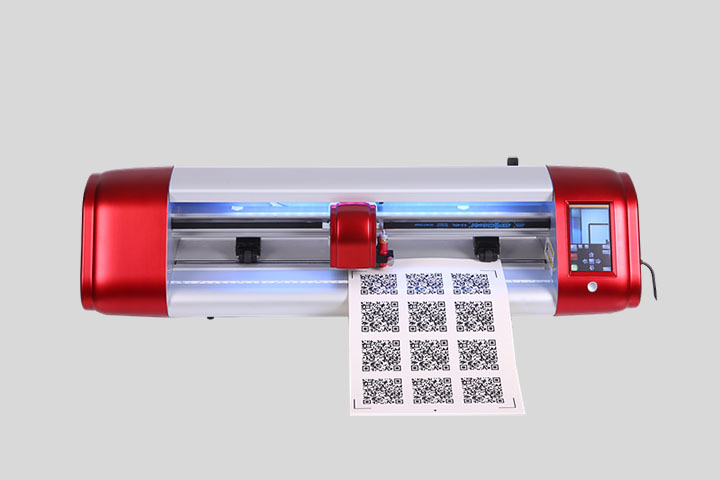

1. Dual cutting heads with a dual carriage system cut the same file at the same time, reducing job time by half.

2. Achieves a cutting speed of up to 1600 mm/s + 1600 mm/s for rapid processing of large batches, in half the time.

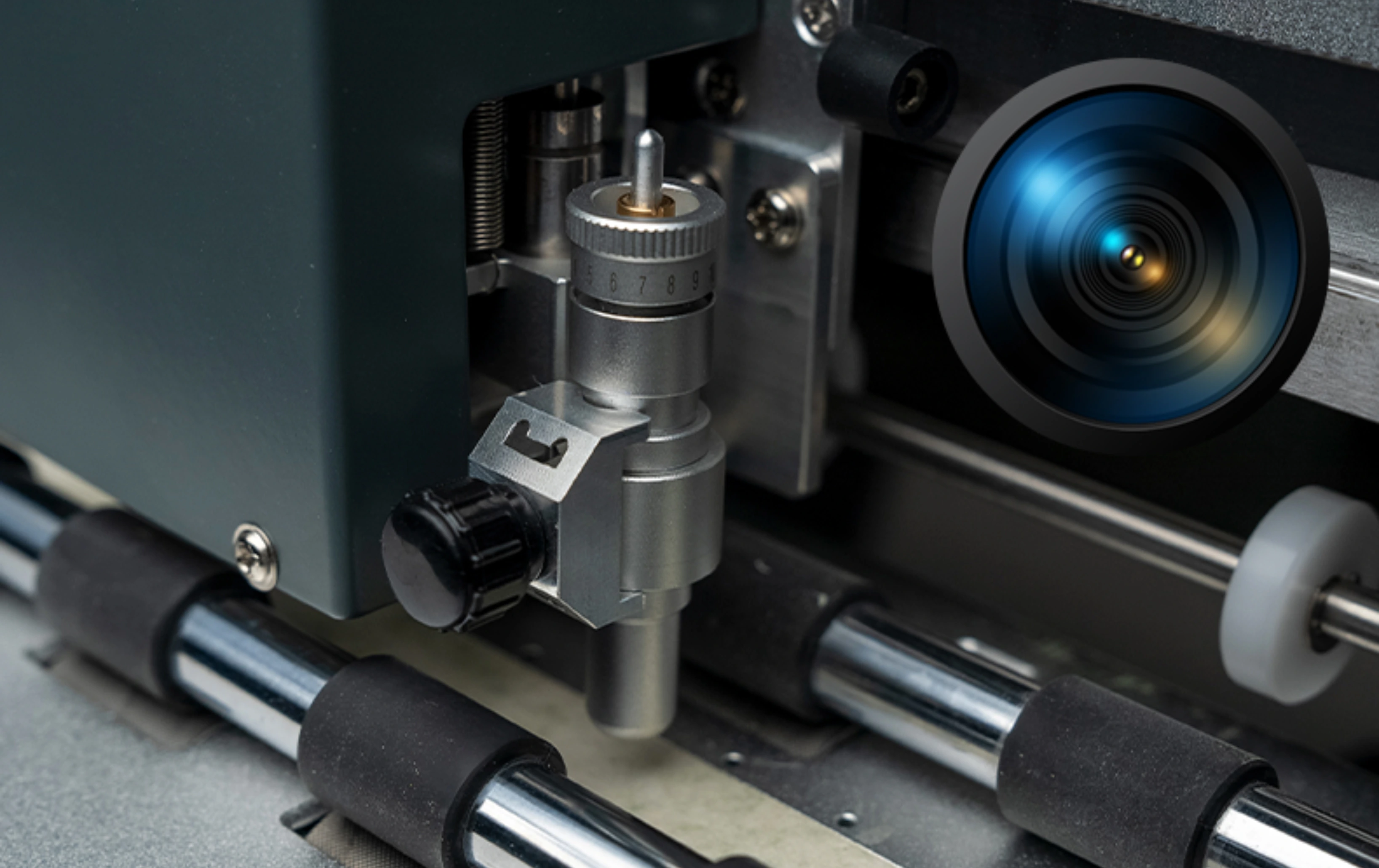

3. Delivers a powerful cutting force of 2000 g, suitable for materials like sticker sheets, cardstock, and laminated paper.

4. Offers high precision with ±0.01 mm accuracy and ±0.082 mm repeatability.

5. 5. Capable of handling upwards of 2000 sheets per day, making it ideal for high-volume production environments and commercial cutting operations.

.webp)

.webp)

.jpg)

.jpg)