1. Automatic waste removal for continuous, clean production.

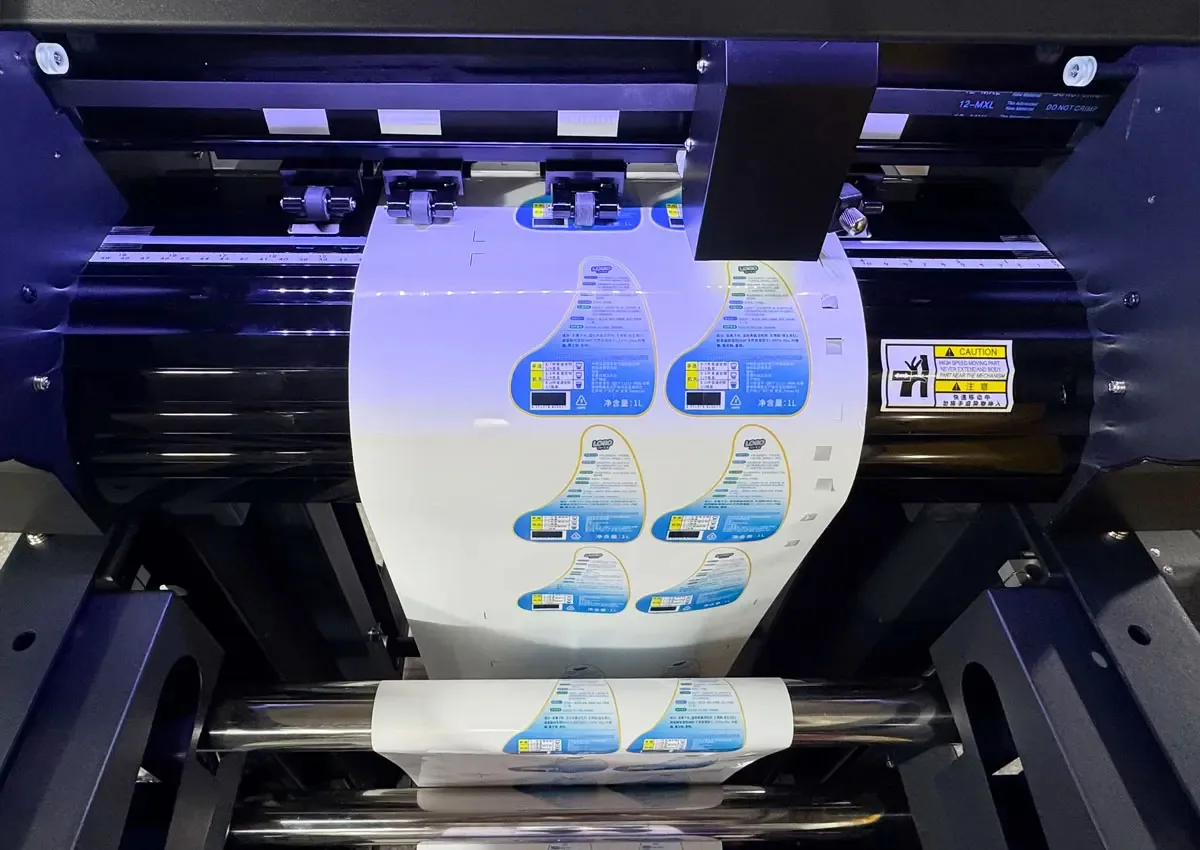

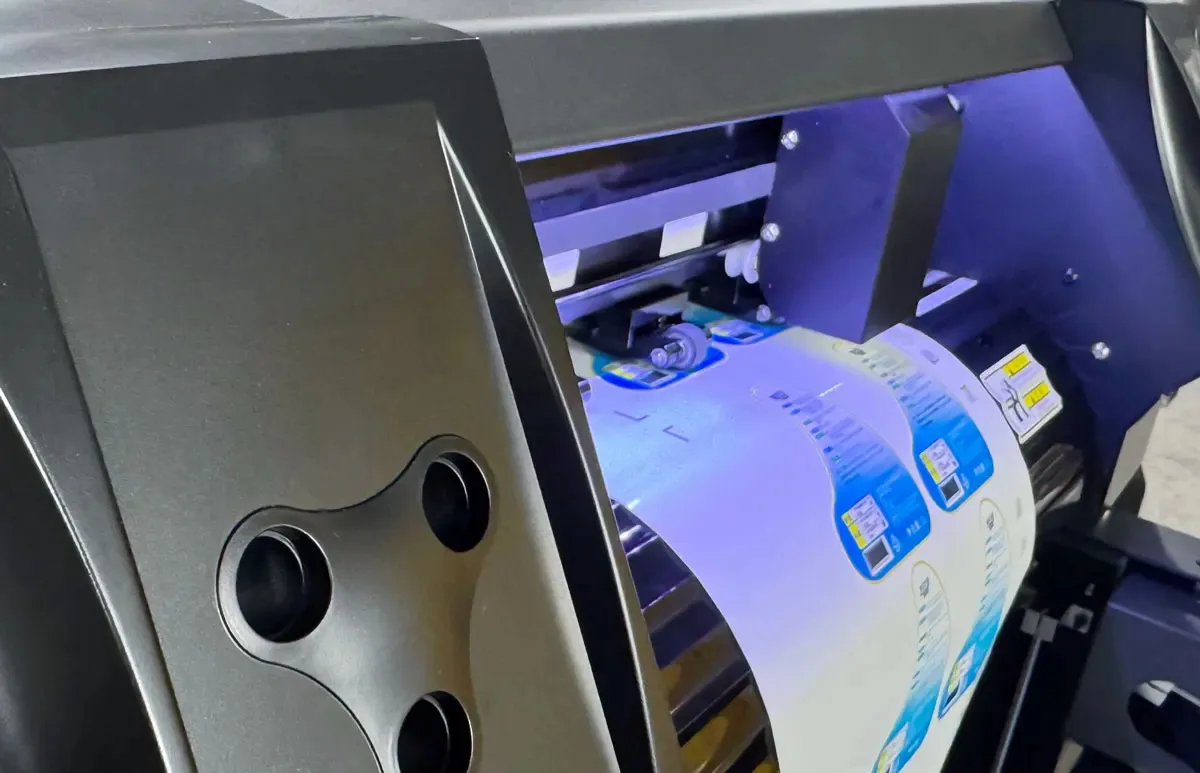

2. Roll-to-Roll continuous label cutting for high-efficiency finishing.

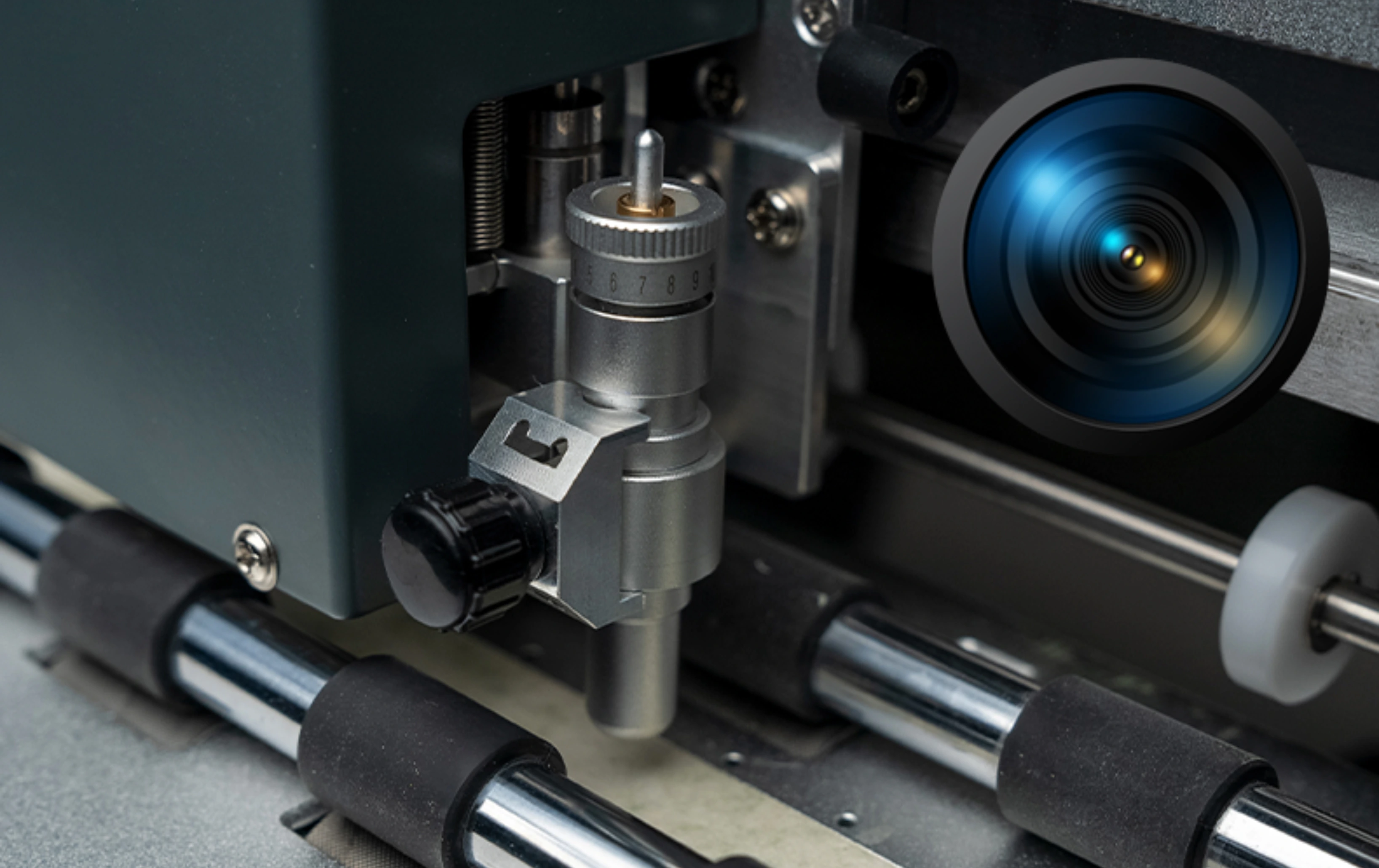

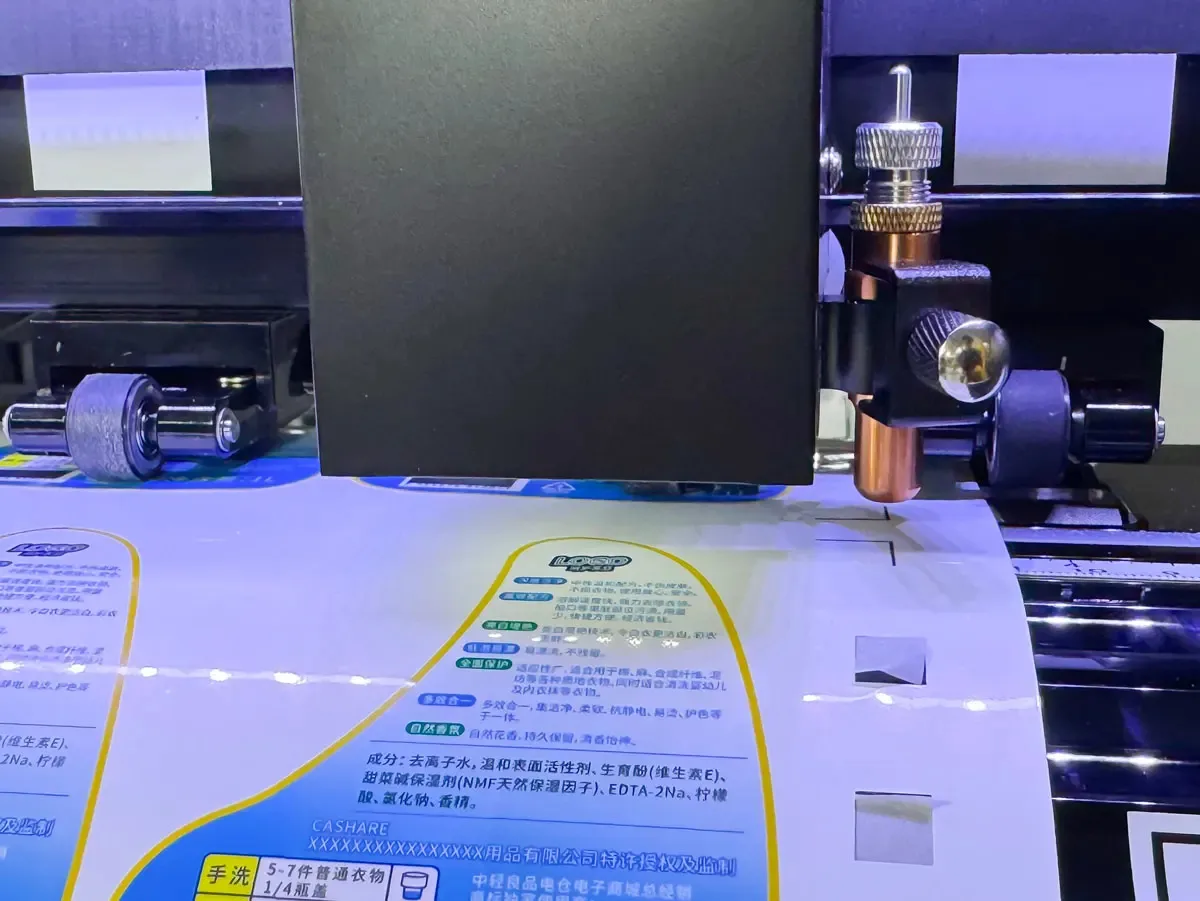

3. Auto contour cut with camera guidance for high accuracy.

4. Scan code and cut workflow to reduce setup time.

5. Emergency stop and die head cutting support.

Specifications

| Product Specifications | |

|---|---|

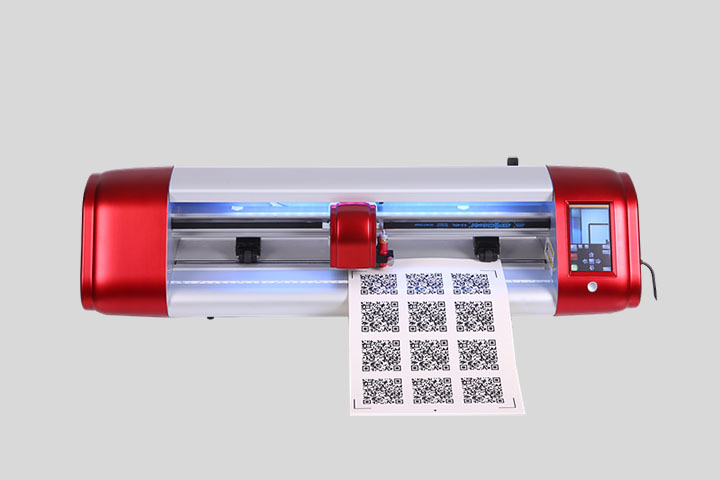

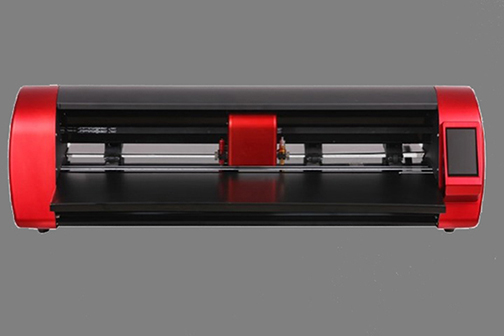

| Product Name | JDJ 330 Roll to Roll Cutting Machine |

| Brand / Model | SKYCUT |

| Max Media Width | 490 mm |

| Max Cutting Width | 330 mm |

| Media Handling | Auto feeding, cutting & waste dealing |

| Cutting Precision | 0.01 mm |

| Repeat Precision | 0.082 mm |

| Max Cutting Speed | 1200 mm/s |

| Max Force | 2000 g |

| Interface | U Disk / WiFi / USB |

| Power Consumption | < 100 W |

| Working Environment | 5 – 35 °C |

| Packing Size | 1330 × 980 × 1250 mm |

| Packing Gross Weight | 120 kg |

Product Description

1. Equipped with a large, full-color touchscreen display, offering an intuitive interface for quick settings, operation control, and real-time job tracking.

2. Includes a built-in stacking tray and auto-sheet feeder, allowing smooth loading and organized stacking of 150–180 sheets for continuous cutting.

3. Delivers a powerful cutting force of up to 2000g, suitable for a wide range of materials including vinyl, cardstock, sticker sheets, and visiting cards.

4. Dual cutting heads with a dual carriage system work simultaneously to cut the same file in parallel, significantly reducing production time—often by up to 50%—while maintaining consistent accuracy and quality across every pass.

Roll-to-Roll Continuous Cutting

Designed for label rolls and long jobs with minimal manual intervention. Stable tension for consistent cuts.

Scan Code and Cut

Camera reads QR/barcodes to auto‑identify jobs and align contours, reducing setup time and errors.

Automatic Waste Removal

Automatically peels and collects matrix after cutting to keep output clean and production continuous.

Die Head Cutting & Safety

Supports die head cutting with servo precision; emergency stop enhances operational safety during production.

.jpg)